Table of Content

Liquid Print offers instructions on everything involved including prepping, painting, hydro dipping to top coating. With over twenty years in the industry we know how to help our customers. Liquid Print provides hydrographic films and activators for manual, semi-automatic and fully automatic water transfer printing systems. Liquid Print provides stock print hydrographic films, branded custom Hydro Dipping / hydrographic films; production custom hydrographic films and custom short run hydrographic films. Liquid Prints hydrographic films are available in sizes from 50 centimeter wide to 1.5 meter wide.

Liquid Print offers a complete in-house hydrographic training program. Our customers have the ability to request what level of training they desire. The water transfer printing process can bring many challenges Liquid Print is here to help.

HYDROGRAPHIC WATER TRANSFER HYDRO DIP FULL KIT ACTIVATOR 1M DIGITAL 4 FILM

DE-GREASE. Do not let the grease from your hands get on the prepared object before dipping. Do this in layers with a waiting time of approximately 10 minutes between layers. Then leave the object to dry for a couple of hours or days depending on conditions.

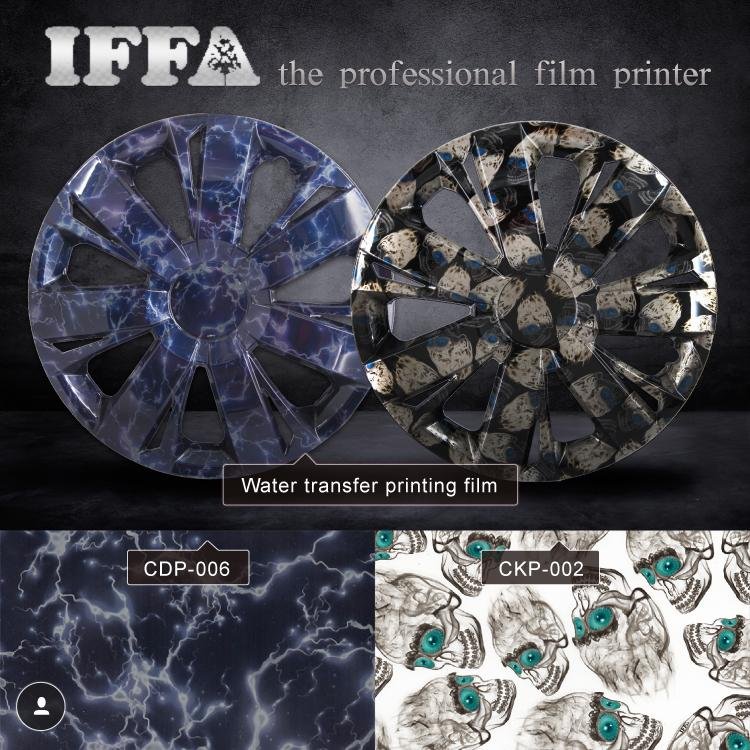

We will work with you to provide visual assessment samples and move forward with full production. Water transfer printing is unique in that the design is printed beforehand and then transferred to the item using standing water. By actually printing the film, complex and consistent designs can be achieved which could not be painted easily. This allows for precise application and professional, repeatable results. You can use any material that can withstand being submerged in water, such as CERAMICS, PLASTICS, METAL and FIBERGLASS. TWN’s Processing Arm provides a consistent and controlled dipping motion for large profile items and custom jigs.

What is My Dip Kit?

TWN’s Curing Systems feature a portable infrared lamp that is used to speed up the curing time of base coats and top coats. Reduce turnaround time and take on more projects with our Infrared Curing System. An adjustable roller coating system pre-activates film and feeds it across the water while a chain drive controls expansion and reduces distortion. Our Continuous Flow equipment is supported by our expansive knowledge base and our Water Transfer Printing consulting services. MyDipKit was designed for the everyday, do it yourself Hydro Dipping enthusiast. The kit contains the basic supplies needed for processing parts at home.

The activator is a chemical that softens the film allowing the inks to float on the water. It’s also activated as the binding agent, ensuring adhesion of the ink to the immersed object. Spraying the right amount of activator evenly is crucial as too much or too little will mess up the transfer. Water transfer printing can be used on a variety of surfaces including wood, metal, plastic, ceramics, and more.

CLEAR COATING

Create enough space to move around and find a container large enough to submerge your object. You can do this indoors or outdoors, but maximum ventilation is key because part of the process involves aerosols, so a confined space might harm you. Whichever you choose, make sure the film is kept away from direct sunlight, heat, moisture, in a cool and dry place until it’s ready to be used. This revolutionary painting technique emerged from Japan in the 1980s. It was readily embraced by car enthusiasts around the world for its incredible ability to coat car parts with custom designs that would be hard or impossible to paint otherwise. Although you may still want to go to a professional for your expensive items, there’s no reason why you can’t try water transfer printing at home.

Hydro-Dip films can be applied to most common shapes or substrates used around the world. The high elongation properties of the film and the dimensional stability in all directions offer excellent and consistent results. Hydro Dip has hydrographic printing experts that can quickly place your project on a path for water transfer printing success.

Hydrographics Training

Our line of Water Transfer Printing Wash Stations features an Open Conveyor System that is the most efficient on the market. Freshly-dipped products are inserted in one side and slowly carried by a durable stainless-steel wire mesh through a 360-degree wash cycle. Our OEM Implementation Program will integrate Water Transfer Printing into your existing production line. Our team has successfully integrated our process into both large and small manufacturing facilities with a minimum amount of downtime. Our Certification Program is the most in-depth Water Transfer Printing training on the market.

Do you have the volume and are ready to bring Water Transfer Printing in-house? TWN provides a suite of automated equipment solutions that provide decorating efficiency at scale. Learn more about our equipment options and schedule a call with one of our consultants to discuss which equipment option will be the right fit for your unique application.

Our Entry-Level fiberglass tank features a lightweight, compact design and is built entirely at our facility in Princeton, Fl. We also offer various sizes stainless steel hydrographic tanks. These tanks feature a Perfect Flow™ circulation pump, Assure Temp™ temperature control, and industrial grade surface heaters. These ensure your tank retains a constant temperature and is optimized for the Water Transfer Printing process.

Once the film is on the water, wait for a minute and spray the activator. This will help the film dissolve and activate the binding agents of the inks. The periods in between the stages (i.e. the drying time) is extremely important and should be adjusted to the weather and temperature conditions of your environment. If desired, attach a makeshift handle to the object using tape to hold on to while dipping. Once the object is out of water, it is allowed to dry, and then sprayed with a clear coat. It seals the design in and protects it from all kinds of damage.

Try dipping a few small items before tackling larger, more expensive items. Just like with the standard My Dip kit we provide customer service online and by phone during normal business hours. Processing Arms are extremely beneficial in operations where consistency and quality are imperative. Our Processing Arm offers a seamless integration with our Automated Spray System and deploys once the film is activated and the set dwell time has expired. Our Automated Spray System features hydraulic spray nozzles that retain constant pressure and ensure proper atomization, without dripping excess activator. The user-friendly touchscreen HMI allows you to program up to 500 unique film profiles directly into your Automated Spray System.

No comments:

Post a Comment