Table of Content

If the film is smaller than the dimensions of the container, you can use tape to block it from floating away. Remember that the temperature of the water needs to be warm, between degrees Fahrenheit. If it’s a wooden or metal object, make sure it’s as even and smooth as possible. Apply primer, let it dry, then apply a base coat of paint, again, let it dry.

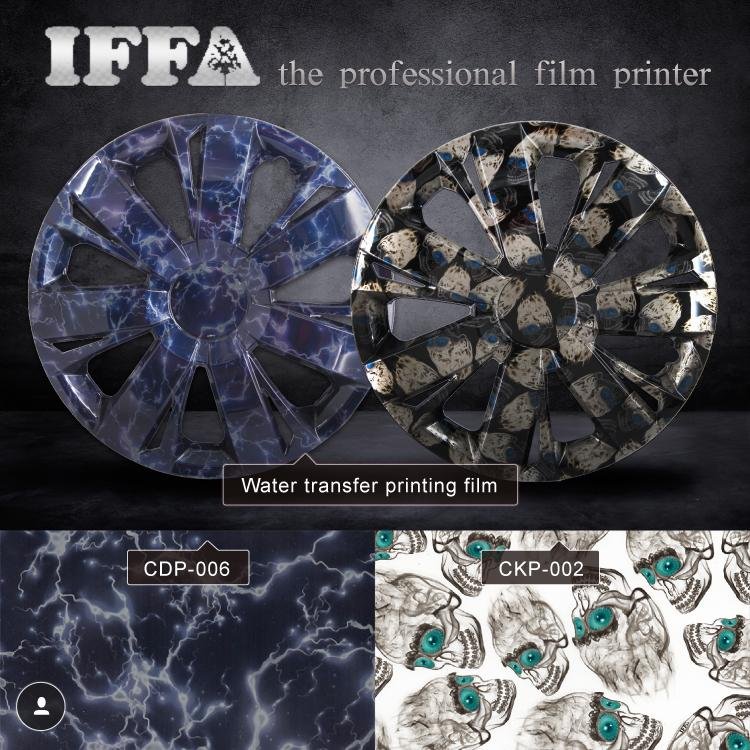

We will work with you to provide visual assessment samples and move forward with full production. Water transfer printing is unique in that the design is printed beforehand and then transferred to the item using standing water. By actually printing the film, complex and consistent designs can be achieved which could not be painted easily. This allows for precise application and professional, repeatable results. You can use any material that can withstand being submerged in water, such as CERAMICS, PLASTICS, METAL and FIBERGLASS. TWN’s Processing Arm provides a consistent and controlled dipping motion for large profile items and custom jigs.

Licensed Camouflage Kits

The base coat or top coat is a layer of paint that covers the entire surface to be printed. It is usually white so as to allow all the colors of the design to be visible. With basic knowledge of color theory, base coat colors can be played with. For example, tan base coats are commonly used for camouflage prints because white would appear glaring.

Our line of Water Transfer Printing Wash Stations features an Open Conveyor System that is the most efficient on the market. Freshly-dipped products are inserted in one side and slowly carried by a durable stainless-steel wire mesh through a 360-degree wash cycle. Our OEM Implementation Program will integrate Water Transfer Printing into your existing production line. Our team has successfully integrated our process into both large and small manufacturing facilities with a minimum amount of downtime. Our Certification Program is the most in-depth Water Transfer Printing training on the market.

What you will need to provide:

DE-GREASE. Do not let the grease from your hands get on the prepared object before dipping. Do this in layers with a waiting time of approximately 10 minutes between layers. Then leave the object to dry for a couple of hours or days depending on conditions.

Hydro dipping, previously known as water transfer printing, is a method of applying printed graphics to three dimensional objects. Hydrodip’s decorative films offer a rich variety of color tone and effect to any three dimensional objects with a paintable surface. Styling options of the paint and film portfolio range from solid colors, brushed aluminum, and various designs including custom made patterns, kevlar and wood grain looks. This process offers image-defining styling options and flexibility in creating decorative coatings that are attractive, stain resistant and easy to clean. Liquid Print is not only the leading North American manufacturer of equipment, hydrographic films and supplies in the Water Transfer Printing industry for over twenty years.

Base Coat

TWN’s Curing Systems feature a portable infrared lamp that is used to speed up the curing time of base coats and top coats. Reduce turnaround time and take on more projects with our Infrared Curing System. An adjustable roller coating system pre-activates film and feeds it across the water while a chain drive controls expansion and reduces distortion. Our Continuous Flow equipment is supported by our expansive knowledge base and our Water Transfer Printing consulting services. MyDipKit was designed for the everyday, do it yourself Hydro Dipping enthusiast. The kit contains the basic supplies needed for processing parts at home.

Hydro-Dip films can be applied to most common shapes or substrates used around the world. The high elongation properties of the film and the dimensional stability in all directions offer excellent and consistent results. Hydro Dip has hydrographic printing experts that can quickly place your project on a path for water transfer printing success.

My Dip Kit Hydro Dipping Kits

In water transfer printing, on the other hand, a thin sheet containing printed ink known as a hydrographic film is laid on the water rather than straight paint. An activator is applied to the film and the object is dipped through. Products are decorated using a print, which resides on a thin base of water-soluble film. The printed film is placed on the surface of the water, and the base begins to dissolve. A patented activator chemical is sprayed over the film causing the ink to remain floating in an oil-like state on top of the water. Next the properly prepared part is immersed into the water, and the upward pressure of the water causes the ink to wrap around and adhere to the item.

Create enough space to move around and find a container large enough to submerge your object. You can do this indoors or outdoors, but maximum ventilation is key because part of the process involves aerosols, so a confined space might harm you. Whichever you choose, make sure the film is kept away from direct sunlight, heat, moisture, in a cool and dry place until it’s ready to be used. This revolutionary painting technique emerged from Japan in the 1980s. It was readily embraced by car enthusiasts around the world for its incredible ability to coat car parts with custom designs that would be hard or impossible to paint otherwise. Although you may still want to go to a professional for your expensive items, there’s no reason why you can’t try water transfer printing at home.

Once the film is on the water, wait for a minute and spray the activator. This will help the film dissolve and activate the binding agents of the inks. The periods in between the stages (i.e. the drying time) is extremely important and should be adjusted to the weather and temperature conditions of your environment. If desired, attach a makeshift handle to the object using tape to hold on to while dipping. Once the object is out of water, it is allowed to dry, and then sprayed with a clear coat. It seals the design in and protects it from all kinds of damage.

Store hydrographic film in a cool, and dry place to avoid heat and moisture from damaging it. Signs of damaged hydrographic film are curved edges, crumpled surface, etc. Lower your prepared object into the water slowly and steadily. If you immerse too quickly, the water will get agitated and the print will not be applied to the object smoothly. Once fully dipped, clear the surface of ink and remove your item.

The Little Dipper is a great tank for smaller parts, and home-based businesses that require a little smaller foot print. This tank will plug directly into your wall and have you dipping like the pros very quickly. The container can be made of any desired material such as plastic, glass or metal. Also, the container should be deep enough that when you process your part it will be totally submersed below the water line. Your container can never be too deep, but it can be too shallow.

No comments:

Post a Comment